Code EK000151

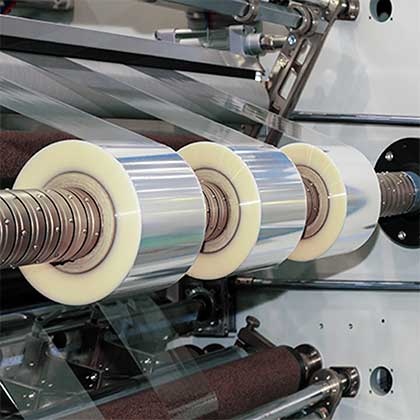

2700 LAEM Film Slitter Machine

LAEM

FILM ROLL SLITTER REWINDERS

The manufacturer of the 2.700 mm LAEM DV 301/1000 has developed a range of machines that are appreciated for the processing and slitting a wide range of materials, focusing especially on all types of flexible packaging which allows to process the most delicate, the most complicated, structured and innovative materials and satisfy customer’s needs. The great experience matured by LAEM has allowed to develop a technology that is a targeted solution esteemed and appreciated by the protagonists of this field.

Technical Data | |||

|---|---|---|---|

REFERENCE MACHINE | DV 301/1000 | ||

MATERIALS | PP, PP+PP, PET+PE, PP+PET MET, PP+PET MET+PE, ALU+PE, PET+ALU+PE, PAPER+PE, PAPER | ||

FILM WIDTH (MAX) | 2.700 mm | ||

TYPE | INDIPENDENT REWIND STATIONS | ||

SHAFTS | 70 / 76 / 152 mm | ||

SPEED | 500 m/min | ||

MAX DIAMETER UNWINDER | 1.000 mm | ||

MAX DIAMETER REWINDER | 1.000 mm | ||

CUTTING SYSTEM | RAZOR BLADES N. 13 | ||

ADDITIONAL INFO | N. 1 GIUGNI PRINTING MACHINE FOR LOGO | ||

Film Slitter Rewinder Machines

A Slitter Rewinder is a machine dedicated to cutting a master or parent roll of material into a smaller width, preparing the material for the subsequent steps of a production process. Essentially, these machines are used to divide a single, wider reel of web into several narrower reels of material.

Slitter rewinders can be found in various types of manufacturing facilities across different industries. These machines are also commonly referred to as slitters, rewind slitters, and roll slitters. Most slitter rewinders are designed for specific types of materials, but they can also be adjusted to handle multiple materials, depending on factors such as the type of material, its dimensions, and the required performance.

In conjunction with material roll specifications, manufacturers often seek out slitting machines that can process specific materials using designated slitting methods or adhere to production requirements like operator ease-of-use, safety, floor space, and speed. Different types of slitting methods include the use of a winder with twin shafts (duplex two shaft) or a double turret slitter rewinder.