Code EK000181

Power Bubble wrap film line

TORNINOVA

AIR BUBBLE FILM EXTRUSION MACHINES

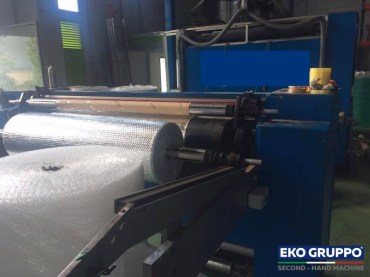

This POWER BUBBLE in-line mono-extrusion is a used high-speed and high-output bubble wrap film machine produced by Torninova.

Thanks to its power and flexibility, the line produces a wide range of bubble wrap films. Starting from an appropriate formulation of LDPE pellets blended with HDPE, PP, LLDPE and mLLDPE, the universal single-screw extruder produces high-performance, low thickness materials.

POWER BUBBLE wrap film used machine

Torninova, in-line mono extruder for bubble film production

Power Bubble mono-extruder is a powerful and versatile system that you can use for various industry applications. In addition to the power and flexibility provided, this machine is also known for producing various air bubble films.

A single operator can control the entire Power Bubble manufacturing process completely, with the system's integrated touch screen controls. In addition, the use of on board network connections make the operation of the machines remotely controlled via the Internet.

Technical data | |||

|---|---|---|---|

REFERENCE MACHINE |

2,5 m / three layers

| ||

STANDARD PRODUCTION SIZE | 650 kg/h (75 g/m2) - 11.250 m2/h (40 g/m2) | ||

DIAMETER OF SCREW EXTRUDER | Ø 130 mm L/D=30 | ||

AVERAGE POWER CONSUMPTION | 125 kW-h | ||

RAW MATERIAL | LDPE pellets | ||

THERMOFORMING PROCESS | With cast extruders | ||

WEB WIDTHS | From 1,25 to 3 m | ||

FINISHED AIR BUBBLE FILM WEIGHT | Min 35 g/m2 - max 600 g/m2 | ||

MAX PRODUCTION SPEED | 75 m/min | ||

FORMING ROLLER DIAMETER | Ø 450 mm | ||

STANDARD BUBBLE SIZE | Ø 10 x 4 mm | ||

CAST DIE | Two separate dies | ||

OPTIONAL EQUIPMENT | TRIPLEX winder, DUPLEX PLUS winder, VIR winder, Third layer extrusion lamination unit, Third layer diathermic oil lamination unit, Third layer hot-air lamination unit, Fourth layer unwinder, Perforation unit, Forming cylinders, Chiller unit | ||