Code EK000184

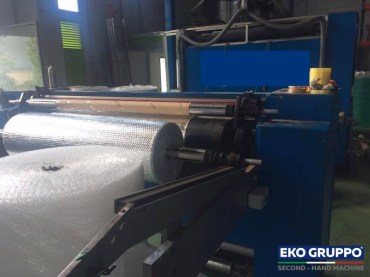

Polyboll Air Bubble Wrap Film Line

TORNINOVA

AIR BUBBLE FILM EXTRUSION MACHINES

POLYBOLL air bubble wrap film line processes LDPE pellets to produce a wide range of excellent-quality air bubble films at moderate outputs.

With its simplified structure and no-frills finishing, the POLYBOLL plant is the most suitable solution for medium-to-small market necessities.

POLYBOLL Air Bubble wrap film line

Torninova, in-line mono extruder for bubble film production

The Polyboll production process of air bubble wrap film (Air bubble film packaging, Reflective bubble foil insulation, Bubble solar pool cover) is completely automatic and fully controllable by a single, un-skilled operator.

This machinery allows a new bracket of customers (e.g. air bubble film distributors and converters) to enter and learn the production market while substantially containing their up-front investment costs.

The Polyboll plant is also ideal for air bubble film manufacturers intending to relocate production facilities directly in distant, but profitable, new markets, while drastically reducing transport costs and amortizing, in the short-term, the initial investment.

Technical data | |||

|---|---|---|---|

REFERENCE MACHINE | 1,6 m / three layers | ||

STARTING STANDARD MATERIAL | pellets of LDPE and LLDPE, mLLDPE | ||

EXTRUDER CAPACITY (MAX) | 130 Kg/h | ||

DIAMETER OF SCREW EXTRUDER |

Ø 80 mm L/D=30

| ||

FILM LAYERS | 2 (3,4 with the adoption of 3rd, 4th layer unit) | ||

NET FINISHED AIR BUBBLE FILM WIDTH | 1.630 mm | ||

THERMOFORMING PROCESS | With cast extruders | ||

FINISHED AIR BUBBLE FILM WEIGHT |

Min 40 g/m2 - max 300 g/m2

| ||

FORMING ROLLER DIAMETER | Ø 270 mm | ||

MAX PRODUCTION SPEED |

30 mt/min

| ||

DIAMETER OF REWINDING ROLL (MAX) | 1.000 mm | ||

AVERAGE ABSORBED POWER FOR BASIC PLANT | 80 kW | ||

STANDARD BUBBLE SIZE | Ø 10 x 4 mm | ||

CAST DIE | One die with double delivery | ||