Code EK000182

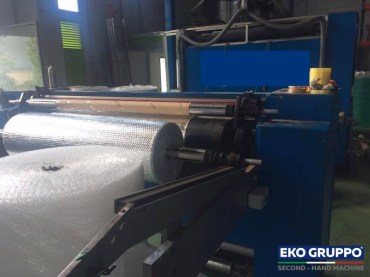

Twin Bubble wrap film machine

TORNINOVA

AIR BUBBLE FILM EXTRUSION LINES

The Twin Bubble wrap film machine allow to produce in-line, in a single step, an air bubble film for insulation applications composed of: two layer of air bubble film laminated with coated aluminium foil on the external side.

This used machine can produce, of course, air bubble film in 2 or 5 layers for the packaging market.

TWIN BUBBLE wrap film used machine

Torninova, in-line mono extruder for reflective insulation materials

The Twin Bubble uses LDPE pellets to produce multi-layer compound (sandwich) bubble foil, PE-foam and aluminum foil, all in a single process. The system basically consists of two "twin" bubble lines producing two bubble foils (laminated with coated aluminum film) in opposite directions; in the middle there is a lamination station that welds the components together. The final multilayer product is then collected on the winder at the end of the line.

The Twin Bubble system has the following characteristics:

- Two extruder for the production, at the same time, of the two layers of air bubble film and one, placed in the middle, for their lamination.

- Two interchangeable forming cylinders Rewinder with automatic cycle that allow to produce rolls from 25 up to 150 mt and more.

- Possibility to add two additional lamination unit by hot air in order to laminate a layer of foam in the centre of the material (between the two layers of air bubble film).

Technical Data | |||

|---|---|---|---|

REFERENCE MACHINE |

1,25 m / five layers double bubble

| ||

STANDARD PRODUCTION SIZE | 1.050 m2/h - 325 kg/h (290 g/m2) | ||

DIAMETER OF SCREW EXTRUDERS | Two (Ø 80 mm L/D=30) + one (Ø 55 mm L/D=30) | ||

AVERAGE POWER CONSUMPTION | 130 kW-h | ||

RAW MATERIAL | LDPE pellets, flame retardant additive, coated aluminum rolls | ||

THERMOFORMING PROCESS | With cast extruders | ||

WEB WIDTHS | From 1,25 to 1,6 m | ||

FINISHED AIR BUBBLE FOIL WEIGHT | Min 80 g/m2 - max 625 g/m2 (double bubble) | ||

MAX PRODUCTION SPEED | 30 m/min | ||

FORMING ROLLER DIAMETER | Ø 270 mm | ||

STANDARD BUBBLE SIZE | Ø 10 x 4 mm | ||

CAST DIES | Two dies with double delivery + one with single delivery | ||

OPTIONAL EQUIPMENT | DUPLEX PLUS winder, VIR winder, Third layer lamination unit by hot-air, Forming cylinders, Chiller unit | ||