. Second-hand machine

Eko Gruppo's used machine

explore our catalogue

. Purchase process

Search our online catalogue and fill out the contact form. Eko Gruppo team will quickly contact you to provide you with the information requested and offer you the best solutions available on the world market for your needs and budget.

. Second-hand machine

Eko Gruppo's technical services

for turnkey projects

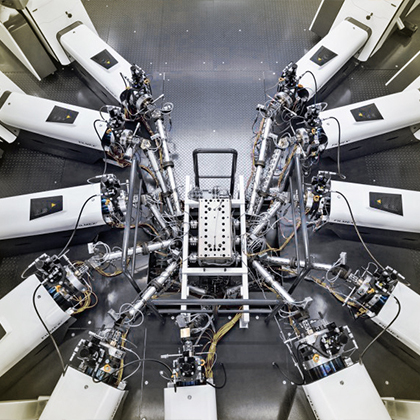

Eko Gruppo can boast a long experience and, thanks to its team of mechanics, electronics, and software specialists, guarantees quality and professionalism to provide with the required services to finalize the purchase of a used industrial machinery: disassembling, packing, shipping, re-installation, commissioning, and start-up.

In addition, the Company ensures consulting and personalized training for the staff in order to speed up the production and processing phases.

You can view some examples of Turnkey Projects on Case Studies.

Disassembly service

Disassembly is a critical process in used machinery to ensure future assembly without any surprises.

Shipping service

Shipping used machinery requires the correct packaging, mode and carrier to avoid any kind of damage.

Reassembly service

Only an expert team guarantees the correct replacement and perfect functioning of used machinery.

Training service

Personalized staff training in the use of used machinery speeds up the processing and production phases.