Code EK000150

Ashe 220-80 Sapphire S2

ASHE

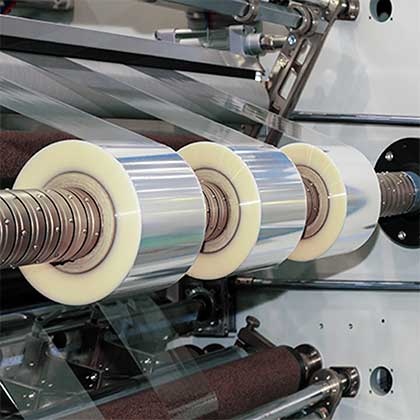

FILM DUPLEX SLITTER REWINDERS

The key benefit for users of ASHE film duplex slitter rewinders is productivity.

Due to turret shaft support the machine is able to offer very fast cycle times, from the time the machine stops when the set length has been reached, to the time it starts the next run.

The machine makes a clean operation for flexible packaging and medical applications and the latest control technology makes the machine easy to use, with a minimal webpath length.

Technical Data | |||

|---|---|---|---|

REFERENCE MACHINE | 220-80 SAPPHIRE S2 | ||

MATERIALS | ALL FLEXIBLE MATERIAL SUBSTRATES | ||

FILM WIDTH (MAX) | 2.200 mm | ||

TYPE | DUPLEX SLITTER - ROTARY SHEAR | ||

TWIN REWINDS | with 76 mm or 152 mm AIRSHAFTS | ||

SPEED | 500 m/min | ||

MAX DIAMETER REEL UNWINDER | 1.300 mm | ||

MAX DIAMETER REEL REWINDER | 800 mm | ||

ADDITIONAL INFO | DRIVEN UNWIND FOR ACCURATE TENSION, SUCTION DRUM, SHAFTLESS FLOOR PICK UP UNWIND, SPLICE TABLE, LOWER SLITTING KNIVES MOUNTED ON AN INFLATABLE SHAFT, FULL WIDTH LAY ON ROLLERS, PUSHER FOR FINISHED ROLL REMOVAL, MOTORISED UNLOADING PEDESTAL WITH ROLL PUSHER, KONGSKILDE EDGE TRIM FAN, TOUCHSCREEN OPERATION | ||

Film Slitter Rewinder Machines

A Slitter Rewinder is a machine dedicated to cutting a master or parent roll of material into a smaller width, preparing the material for the subsequent steps of a production process. Essentially, these machines are used to divide a single, wider reel of web into several narrower reels of material.

Slitter rewinders can be found in various types of manufacturing facilities across different industries. These machines are also commonly referred to as slitters, rewind slitters, and roll slitters. Most slitter rewinders are designed for specific types of materials, but they can also be adjusted to handle multiple materials, depending on factors such as the type of material, its dimensions, and the required performance.

In conjunction with material roll specifications, manufacturers often seek out slitting machines that can process specific materials using designated slitting methods or adhere to production requirements like operator ease-of-use, safety, floor space, and speed. Different types of slitting methods include the use of a winder with twin shafts (duplex two shaft) or a double turret slitter rewinder.